The Safestrip System has been pioneered from hands-on experience of asbestos removal and is the only fully controllable, deep penetration, fine needle automatic injection system available on the market. There is a flow control valve at each needle injection point, to enable delivery of the wetting fluid where it is required, at the rate at which the A.C.M. (asbestos containing material) can absorb it through capillary action.

The Safestrip System has been pioneered from hands-on experience of asbestos removal and is the only fully controllable, deep penetration, fine needle automatic injection system available on the market. There is a flow control valve at each needle injection point, to enable delivery of the wetting fluid where it is required, at the rate at which the A.C.M. (asbestos containing material) can absorb it through capillary action.

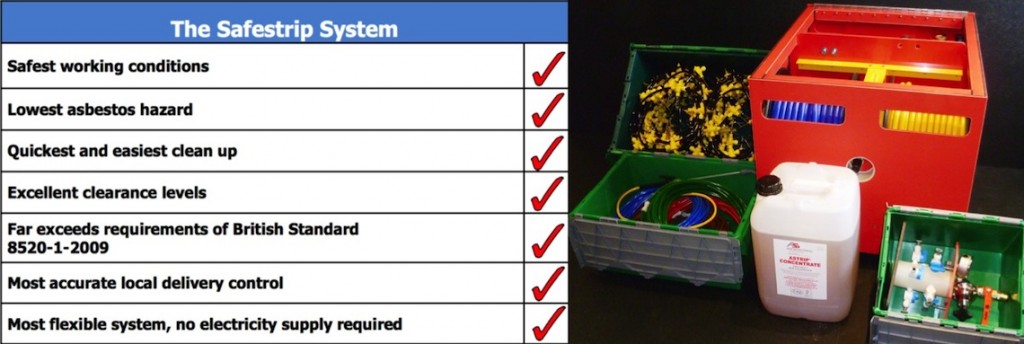

The Safestrip System can cope with any contract, small or large. It is easily transportable, robust, requires no electricity and automatically dilutes Astrip Concentrate Wetting Fluid at 10:1.

The Safestrip System is the only controlled wetting equipment that complies with the BSI PAS 60-1 (British Standards Institution Publicly Accessible Specification) Part 1: Controlled Wetting of asbestos-containing materials specification.

Specification

The Safestrip controlled wetting system comprises of :

1 x Polypropylene unit, red leather embossed, mounted on 2 x 125mm fixed castors & 2 x 125mm swivelling castors, with top lid.

Dimensions 750mm long x 665mm wide x 675mm high. Weight 65kg.

- 1/2″ x 50m (blue) water inlet hose on reel.

- 3/4″ isolating ball valve.

- Water strainer, 3000 litres per hour capacity x 70 microns.

- Remote pressure zone backflow prevention valve.

- Pressure regulating valve, set to 6 bar (90 psi) with pressure gauge.

- Pressure relief valve, set to 6 bar (90 psi), factory sealed.

- Proportional diluting pump ( 10:1 )

- Static mixer for Astrip/water.

- 3/4″ isolating valve.

- 1/2″ x 50m (yellow) hose on reel.

1 x Distribution manifold comprising of:

- Push in hose connector.

- Inlet shut-off valve.

- Pressure regulating valve.

- Manifold body with 8 outlets, each with 3/8″ shut off valve & 3/8″ push in

- connectors fitted with stop plugs.

1 x Polypropylene box with interlocking lids containing:

- 200 x wetting agent flow control valves with 3/8″ push in connectors (a total of 200 x 2″ Injector Units)

- Colour coded extension tubes, 3/8″ diameter with push in connector:

5 @ 2m Blue Tube

5 @ 3m Green Tube

5 @ 4m Red Tube

5 @ 6m Brown Tube

- 1 x Hand Spray

- 1 x Safestrip System Instruction Manual

N.B. This unit is capable of delivering from between 10 and 2000 litres an hour.

Why use the Safestrip System over any other injection system for removal of asbestos?

Performance

- 1200 simultaneous injection points possible

- Extremely low fibre release, if any, during use with Astrip Concentrate

- Greater production rates from workforce during A.C.M. removal

- System will run day or night without supervision

- Quicker clean up time

- The wetting fluid Astrip Concentrate is acknowledged to be the most effective available in the world

Usability

- Very easy to use

- Ergonomically designed to meet operating needs

- Colour coded tubing for easy length selection

- Quick release couplings used throughout

Maintainability

- Minimal maintenance required

- Needle valve assemblies do not require flushing after use with Astrip

- Concentrate

- Unit situated outside the enclosure therefore does not get

- contaminated

Features

- Robust and self contained

- No electricity required – one connection to the water supply

- l00m of inlet and supply hose

- Automatic Astrip Concentrate/water dilution system

- High quality product

- Full selection of accessories available to run off the system

Back-up

- Training & advisory service following purchase with 6 months warranty

Value for money

- Proven over 15 years of on-site projects